Why choose Metal Bending, Punching & Stamping Service’s custom OEM metal stampings, especially combined with Power Coating technology?

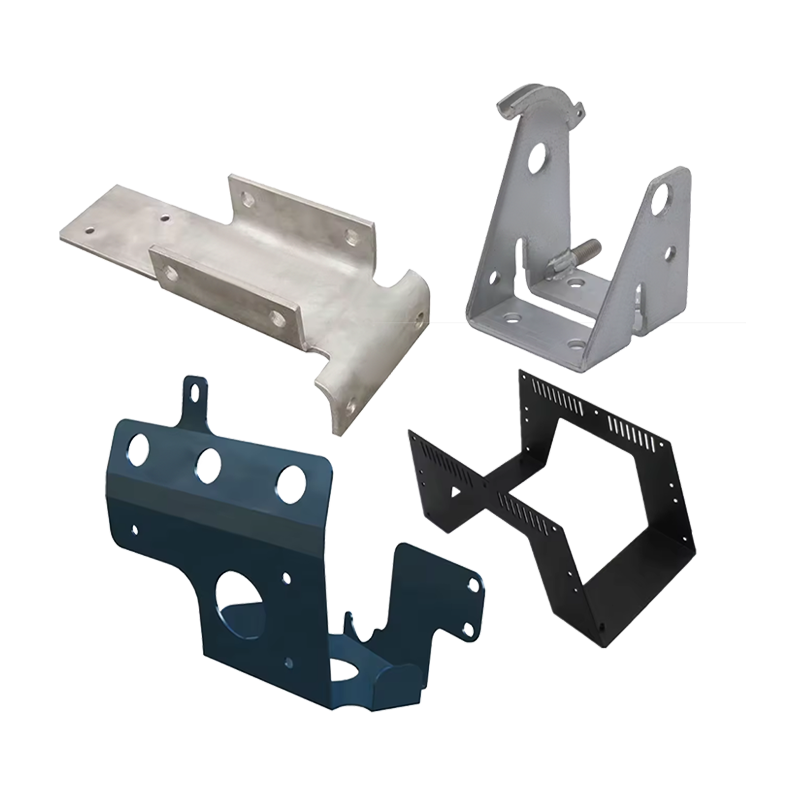

Ningbo Dasheng Metal Products Co., Ltd. manufactures metal parts through stamping, deep drawing and welding technologies to meet various needs in many industries. Our experienced team works closely with our customers to create custom parts that fit exactly to their specifications. From material selection and innovative tool design to precision fabrication of finished products, we use our expertise to ensure products not only meet your exact specifications, but also meet our strict quality standards. Metal bending, punching and stamping services have good workmanship, allowing us to handle complex sheet metal shapes with ease, achieving high precision and efficiency in custom production processes. From complex electronic component housings to large mechanical parts, our broad product portfolio demonstrates our expertise in metal stamping. Using the most advanced CNC equipment and precision molds.

In the production process of metal stamping parts, Power Coating is a key process that significantly improves the anti-corrosion and aesthetics of the product. Compared with traditional paint coating, powder coating has the following significant advantages:

Good anti-corrosion performance: Powder coating is composed of corrosion-resistant resin materials, which can form a dense and strong adhesion coating, effectively isolate the metal from corrosive media in the environment, thereby extending the service life of stamping parts.

Environmentally friendly and pollution-free: Powder coatings do not use organic solvents during the coating process, produce no harmful gas emissions, and comply with modern environmental protection requirements. This is undoubtedly an important plus for companies that pursue green production and pay attention to environmental responsibility.

Cost-effective: Powder coatings have a high recycling rate, reducing production costs and waste disposal expenses. At the same time, a thicker coating can be obtained in one coating, which reduces the construction process and energy consumption.

Beautiful and durable: Powder coating has a smooth and delicate surface and good gloss, which can improve the overall beauty of stamped parts. The rich color choices also provide customers with more personalized customization possibilities.

English

English 中文简体

中文简体 Español

Español