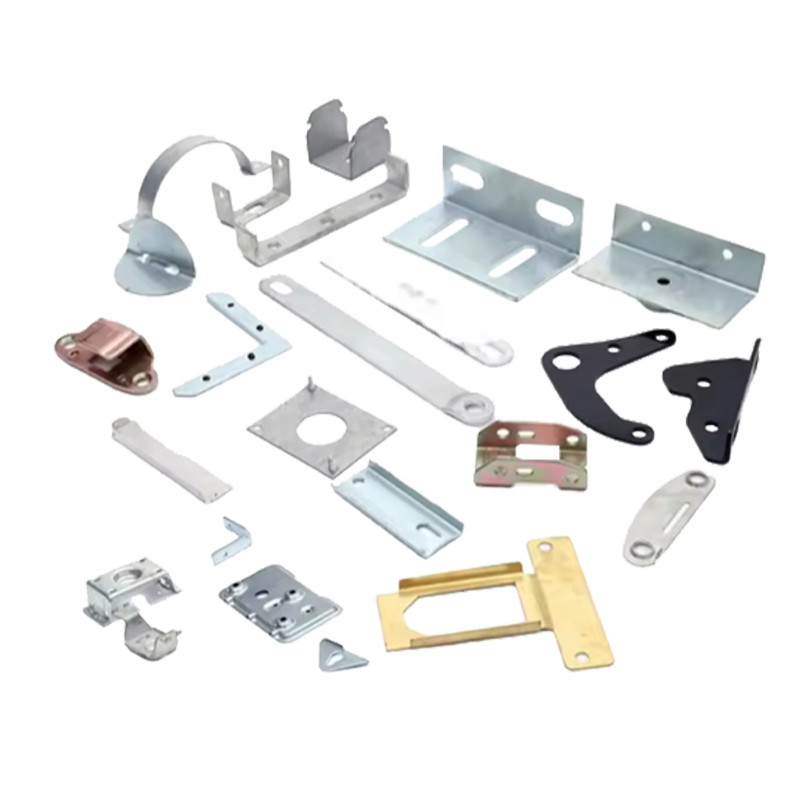

Why Sheet Metal Powder Coated Steel Aluminum Bending Welding Frame Parts Become the Best Choice in Modern Manufacturing?

Ningbo Dasheng Metal Products Co., Ltd. is a provider of precision parts and components for a wide range of industries. Our experienced team works closely with our customers to ensure that each part is made to their exact specifications and meets the highest quality standards. At the core of our manufacturing strength is welding technology, which is a key link in the manufacture of Sheet Metal Powder Coated Steel Aluminum Bending Welding Frame Parts. This technology not only facilitates a strong, sealed connection between steel and aluminum materials, but also expertly adapts to complex shapes and sizes to ensure structural integrity and reliability. The advent of automated welding processes within factories has revolutionized productivity, allowing us to increase efficiency while maintaining unwavering standards for welding quality and consistency. Therefore, Ningbo Dasheng Metal Products Co., Ltd. is always committed to providing customized solutions that exceed expectations, leveraging cutting-edge welding technology to create the future of metal manufacturing.

Precise Control of Bending Process: Bending is another important process in the manufacturing process of frame parts. Through precise bending processes, steel and aluminum materials can be processed into a variety of desired shapes and angles to meet the design needs of different products. The close combination of bending process and welding technology makes Sheet Metal Powder Coated Steel Aluminum Bending Welding Frame Parts more flexible and diverse in structural design and manufacturing.

Innovative application of powder coating: Powder coating, as an environmentally friendly and efficient surface treatment technology, has been widely used in the manufacture of Sheet Metal Powder Coated Steel Aluminum Bending Welding Frame Parts. Powder coating not only has excellent corrosion resistance, weather resistance and wear resistance, but also can be customized in different colors and glossiness according to customer needs to enhance the aesthetics and added value of the product. At the same time, powder coating can also effectively protect welding joints and bending parts from erosion and damage by the external environment.

High strength and stability: The high-strength connection achieved by welding technology and the precise structure formed by the bending process of Sheet Metal Powder Coated Steel Aluminum Bending Welding Frame Parts have significantly improved its overall strength and stability. This frame component can withstand large loads and impacts, ensuring the stable operation of the product in various harsh environments.

Good sealing: The tight weld formed during welding and the precise docking during the bending process make Sheet Metal Powder Coated Steel Aluminum Bending Welding Frame Parts have excellent sealing performance. This sealing performance is particularly important for occasions where gas, liquid or solid particles need to be prevented from penetrating, such as automobile manufacturing, aerospace and other fields.

Beauty and durability coexist: The innovative application of powder coating not only enhances the beauty of Sheet Metal Powder Coated Steel Aluminum Bending Welding Frame Parts, but also enhances its durability. Powder coating can resist the erosion of various corrosive media and the irradiation of ultraviolet rays, maintain the surface finish and color brightness of the product, and extend the service life of the product.

Sheet Metal Powder Coated Steel Aluminum Bending Welding Frame Parts has been widely used in many fields with its good craftsmanship and good performance. In the field of construction, they are used as structural components such as door and window frames and curtain wall supports; in the industrial field, they are used to manufacture support and connection components of equipment such as mechanical equipment and automated production lines; in the field of transportation, they have become an important part of transportation tools such as cars, trains, and airplanes.

English

English 中文简体

中文简体 Español

Español